If you find my tutorials helpful, you can support CADCAMLessons:

https://ko-fi.com/cadcamlessons

Lead In/Out – Line – Alphacam

YouTube: https://youtu.be/TRjahOTbe5E

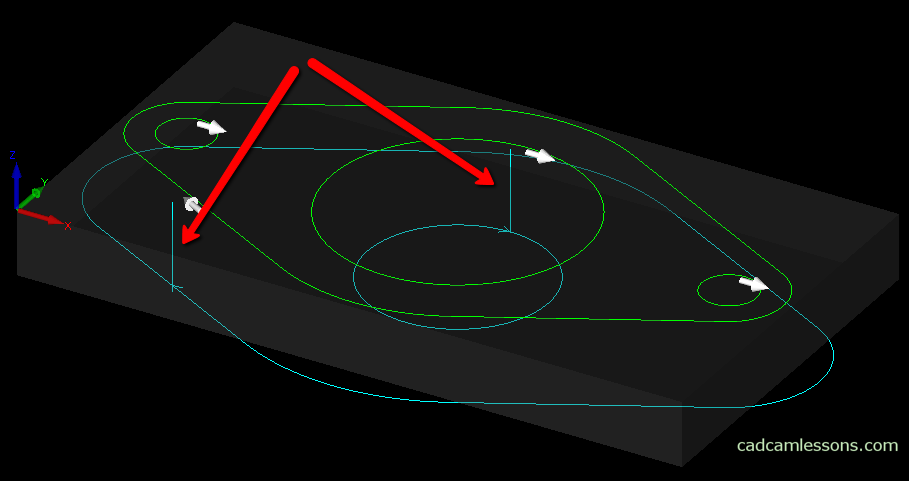

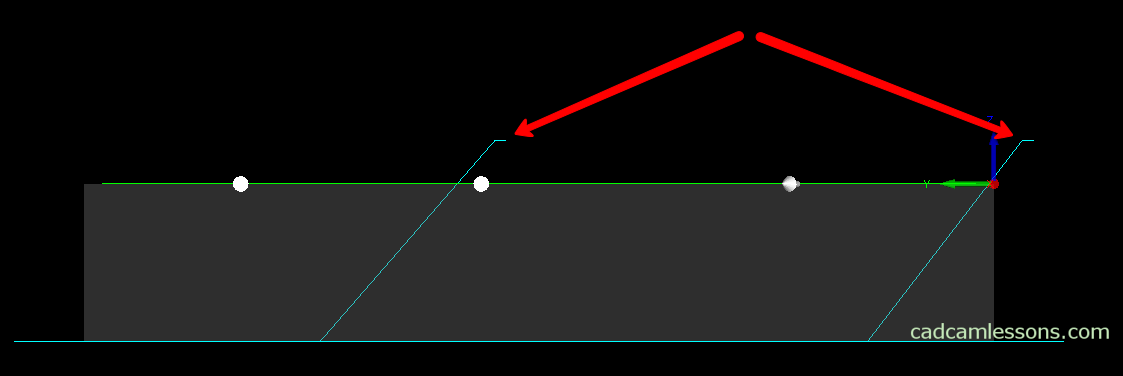

Before we run the simulation, based on the appearance of the tool paths, we could see that the tool’s entry into the material is not very good.

We see that the tool goes down vertically. As is the drilling. For cutters, this kind of entry into the material is not very good.

Of course, in Alphacam, it is very easy to change and adjust the tool entry to our needs.

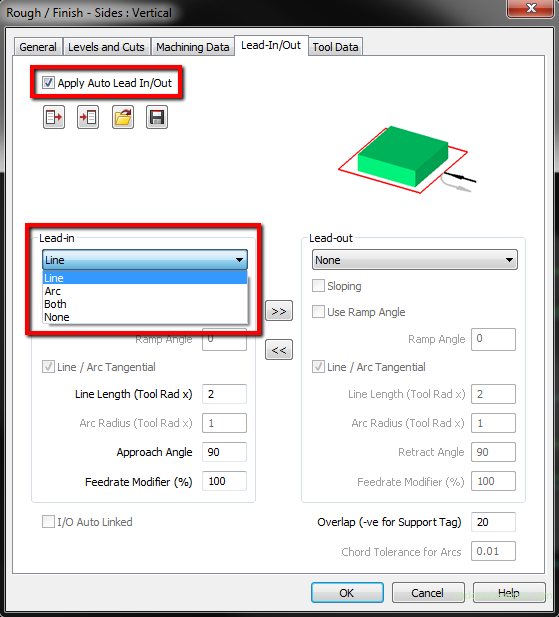

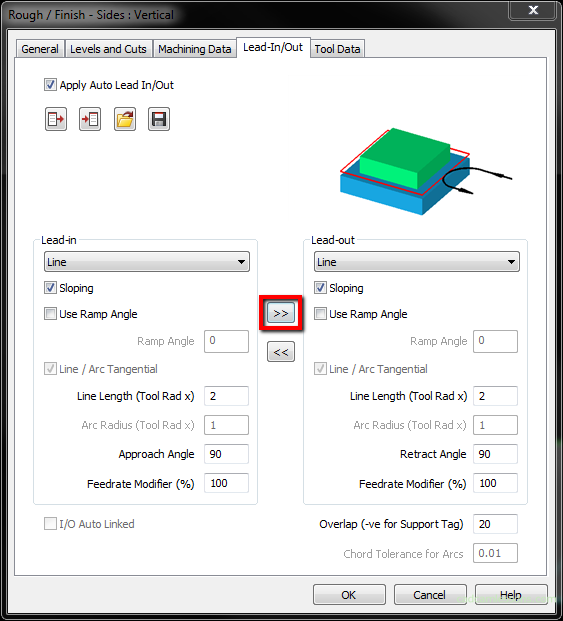

Edit the operation (click the RMB for the operation and select Edit) and go to the Lead-In/Out tab.

To enable adding the tool in and tool out, select the option Apply Auto Lead In/Out.

We will focus mainly on the entry of the tool into the material, because the exit has the same parameters. Therefore, in the Lead-In section, select Line from the drop-down list. And in the Lead-Out section, select None from the list.

Set the other parameters as in the drawing above and click OK to check what has changed.

For line entry, we have the following parameters:

Line Length (Tool rad x) – this is the length of the tool entry line. The parameter in itself, does not mean the length of the line. This is the tool radius multiplier. So, if we enter the value 2 in this field, the length of the line will be 2 x the radius of the tool.

Approach Angle – this is the angle of the entry line relative to the tool path at the entry point (I suggest you check the different values to see how the tool path will react to the parameter change).

Feedrate Modifier (%) – we can modify the feed rate for the tool input into the material. We can increase or decrease the feed rate at the entry by entering the percentage of feed set in the Tool Data tab.

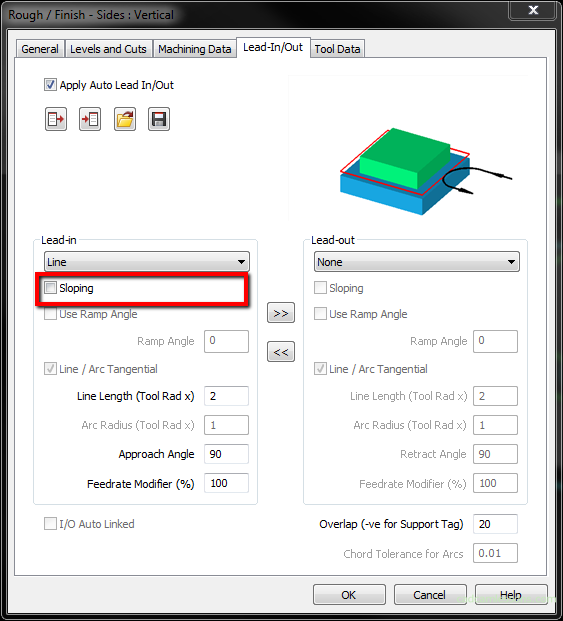

Below the list of entry types is the Sloping parameter.

Let’s select this parameter and check how the tool in changes.

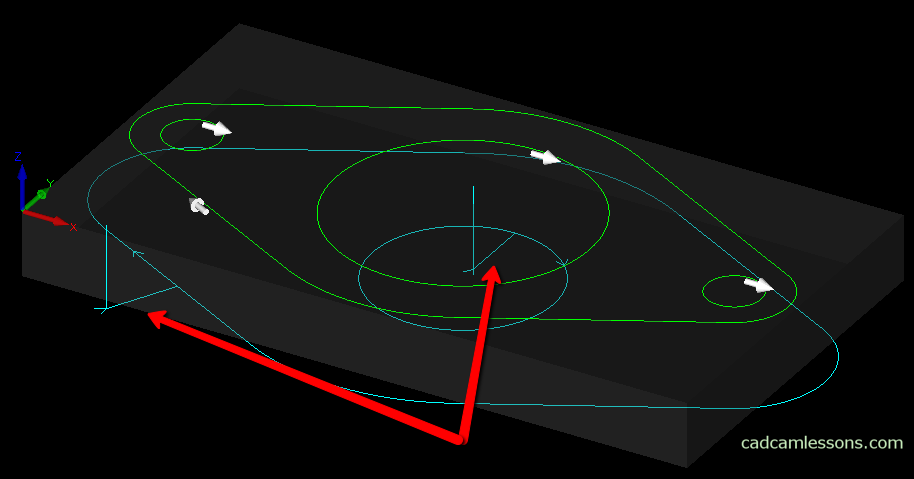

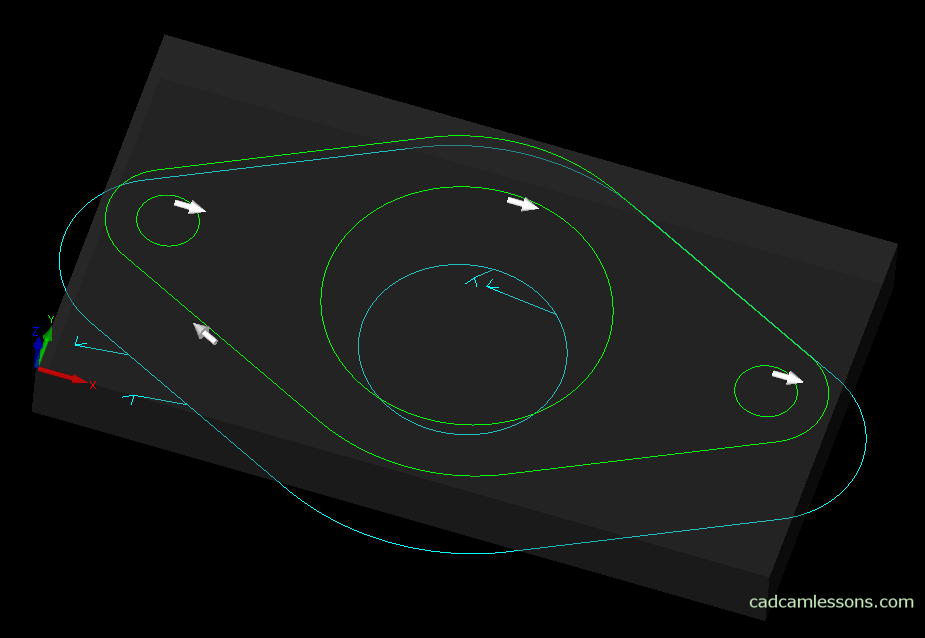

You can see that the tool goes down into the material at an angle. And now I will show you how to quickly add a tool exit with the same parameters as tool entry.

If you click the button marked with >>, the tool input parameters will be copied to the tool output. If we would like to copy the parameters of the tool output to the tool input, it is enough to click the button <<.

Click OK and check the path of the tool.

We have the same parameters for the tool in and tool out, but why is the entry point and exit point not in the same place?

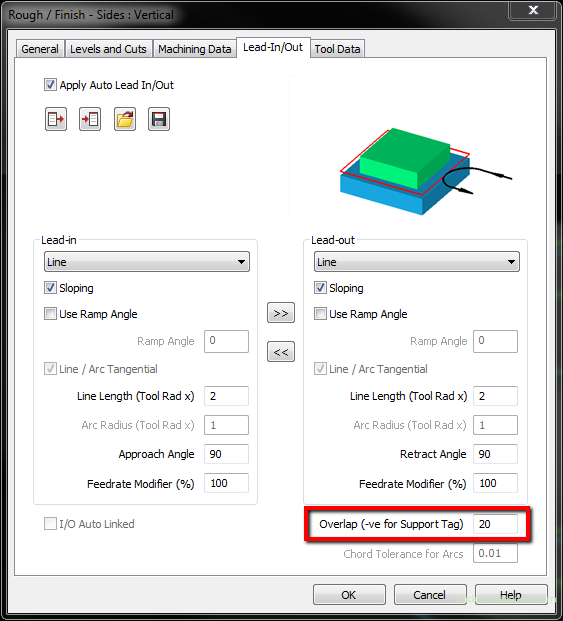

Because we have a value of 20 in the Overlap parameter.

This is the value by which the tool’s exit point will be shifted, relative to the tool’s entry point. And it will cause that the tool’s exit point will not coincide with the tool’s entry point.