Beginner’s Guide: Embracing CAM Software in Small-Scale Manufacturing

Introduction

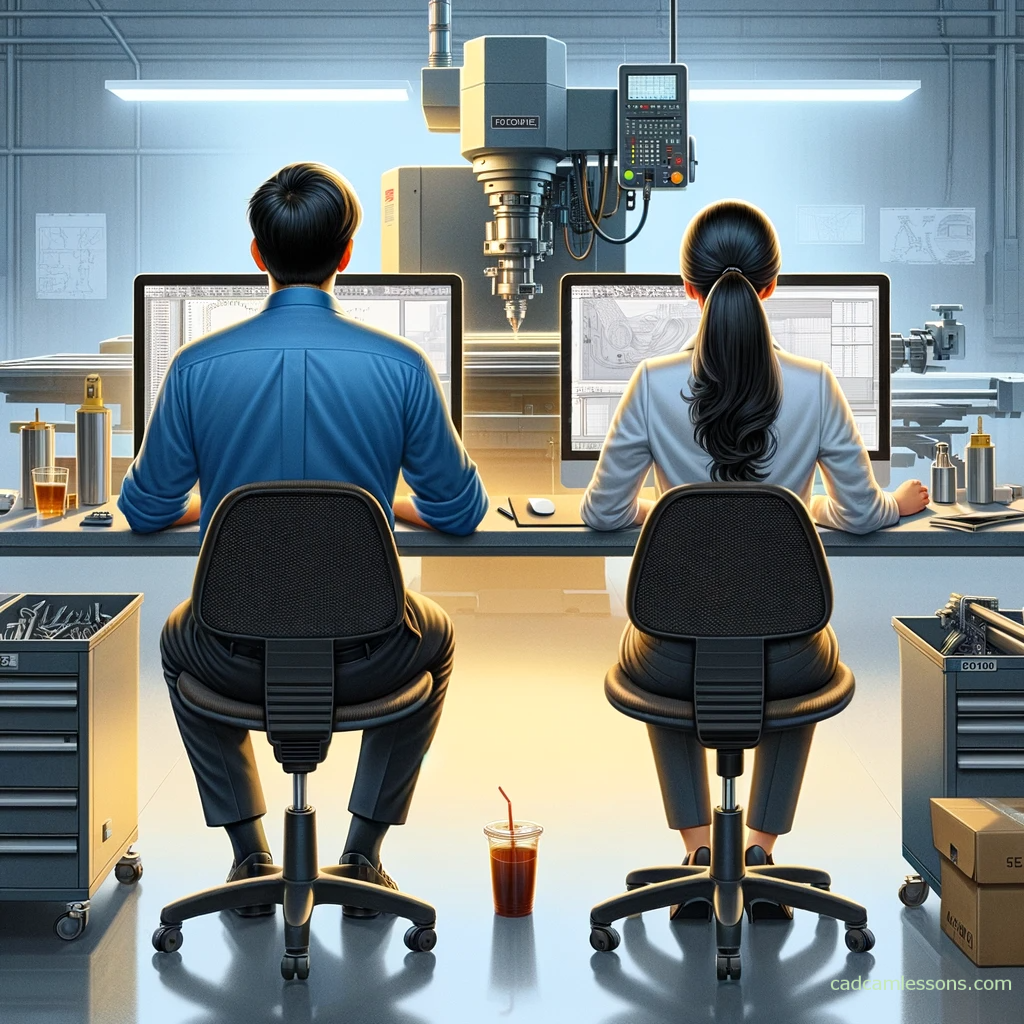

In the ever-evolving world of small-scale manufacturing, efficiency and cost reduction are paramount. A key player in this arena is CAM (Computer-Aided Manufacturing) software. This guide aims to introduce CAM software, highlighting its applications, benefits, and essential concepts for small businesses.

What is CAM Software?

CAM software serves as a bridge between digital designs created in CAD (Computer-Aided Design) software and the production process. It translates these designs into precise instructions for manufacturing machines like CNC (Computer Numerical Control) milling machines, enabling quick and accurate production of parts and components.

Why Should Small Businesses Consider CAM Software?

- Enhanced Efficiency

- Automated Processes: CAM reduces production time by automating tasks that previously required manual intervention.

- Precision and Consistency: It ensures high accuracy in manufacturing, crucial for complex components.

- Cost Reduction

- Less Material Waste: Precise cutting and processing reduce waste.

- Optimized Machine Usage: Efficient machine time management cuts down on energy and maintenance costs.

- Production Flexibility

- Adaptability to Design Changes: Quickly adjust to project alterations without extensive rework.

Choosing the Right CAM Software

The selection should align with the business’s specific operations. Key considerations include:

- CAD Compatibility: Ensuring smooth integration with existing CAD software.

- Ease of Use: Especially important in small businesses where employees may have multiple roles.

- Functionality: Meeting the specific production needs.

- Cost: Both initial investment and long-term maintenance.

Getting Started with CAM Software

- Training and Education: Invest in employee training for effective use of the new software.

- Testing and Evaluation: Experiment with various CAM software options to find the best fit.

- Integration with Existing Processes: Ensure the new software integrates well with current production systems.

Conclusion

Implementing CAM software in a small manufacturing business can be a game-changer. It not only boosts efficiency and precision but also opens doors to new business opportunities. Remember, success hinges on choosing the right software, tailored to your business needs and capabilities, and investing in employee training.