Alphacam for beginners – Rough or Finish operation

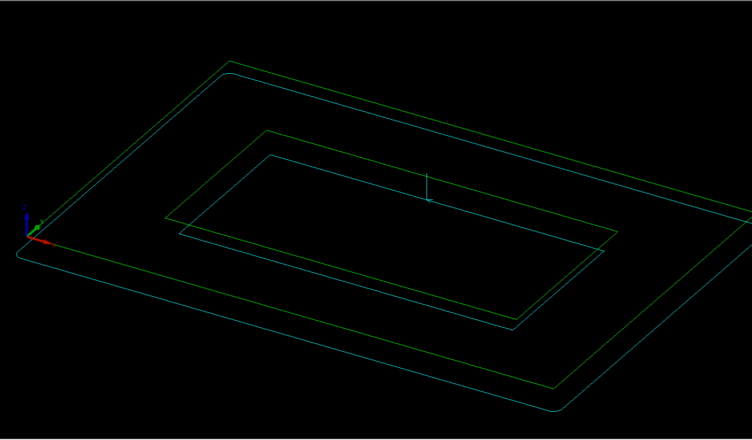

In this lesson I will show you the first step when it comes to contour machining. It is Rough or Finish operation in Alphacam. We want to machine the rectangle 200x100x16.

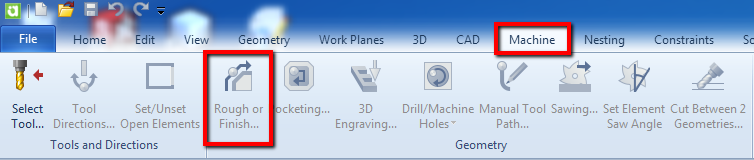

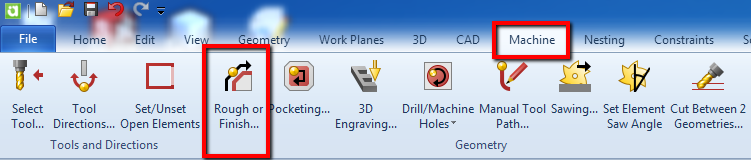

This operation is in the Machine Tab.

But it is not active. The first step is a tool selection.

Click on the Select Tool option.

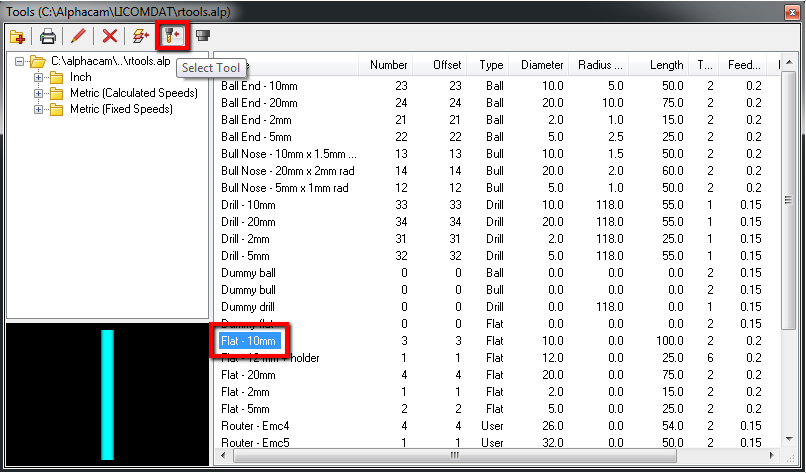

Windows shown bellow will appear.

The default folder for router tools is a C:\Alphacam\LICOMDAT\rtools.alp

I recommend you save all your tools in this folder or some sub-folders in this folder.

OK, you can select the tool using two methods. First one, select the required tool and click on Select tool icon.

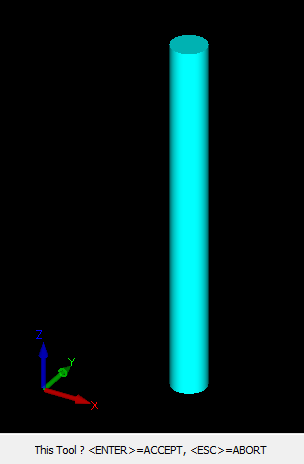

Now you have tool stick to the mouse pointer.

To select this tool click left mouse button on the Alphacam workspace or press Enter.

The second way for tool selection, double click left mouse button on required tool and after that click left mouse button on the Alphacam workspace.

Now, the operation is active and you can select the Rough or Finish operation from the Machine Tab.

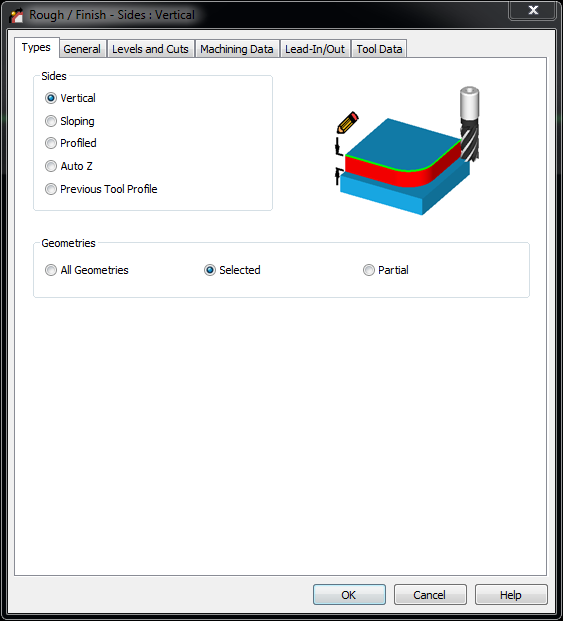

After the selecting this option window shown bellow will appear.

We have few Tabs and parameters. Let’s check other tabs we leave the default parameters in most option.

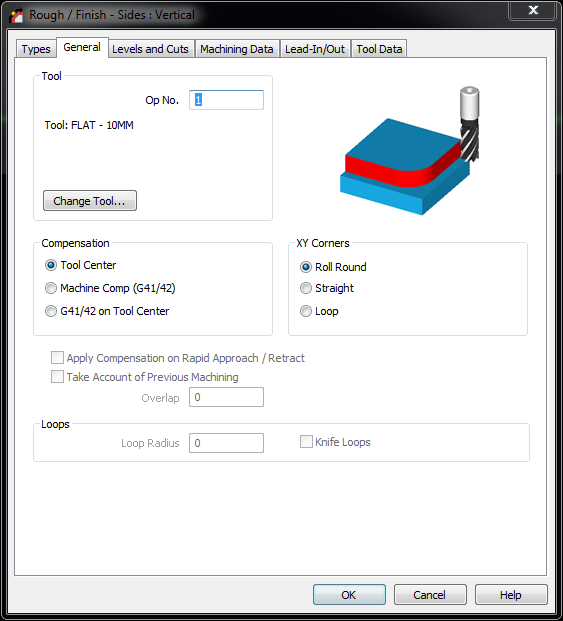

General Tab

Levels and Cuts tab

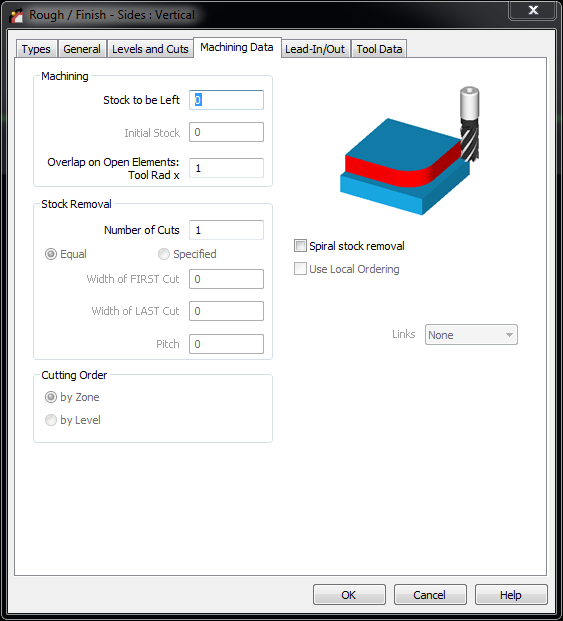

Machining Data tab

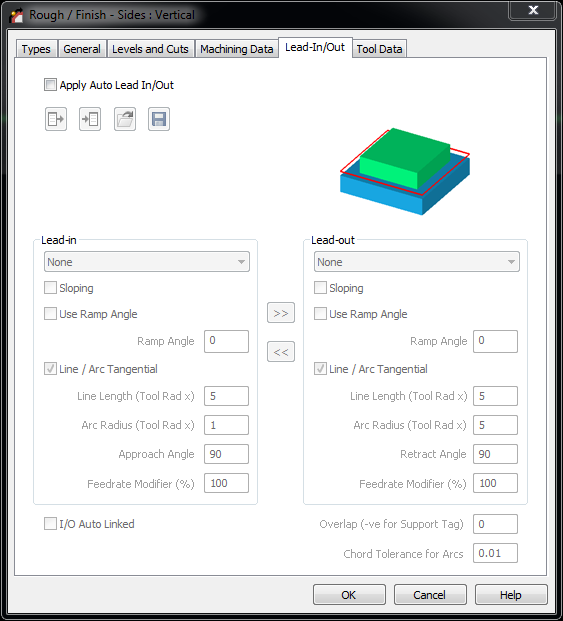

Lead-In/Out tab

Tool Data tab

Click OK and now you have to select geometries.

Select the rectangle and accept selection by clicking right mouse button or Finish (ESC) button or Esc key.

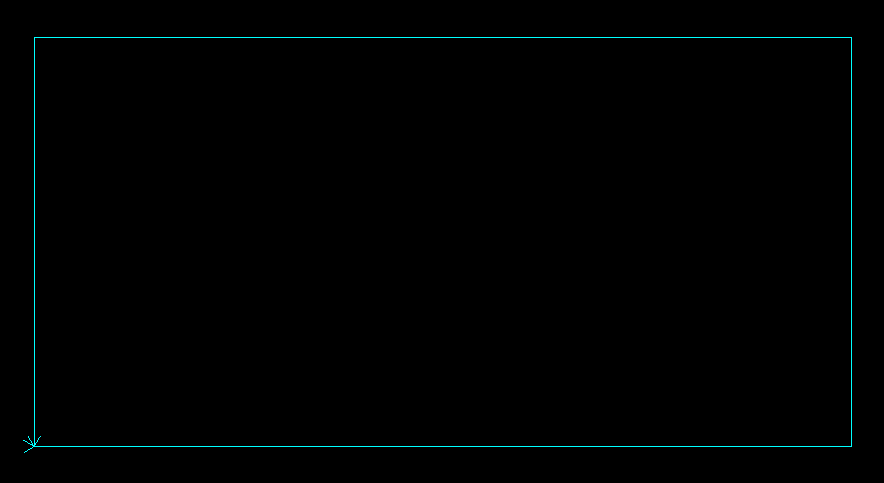

And you will get:

This light-blue line is a tool path (and it is wrong tool path).

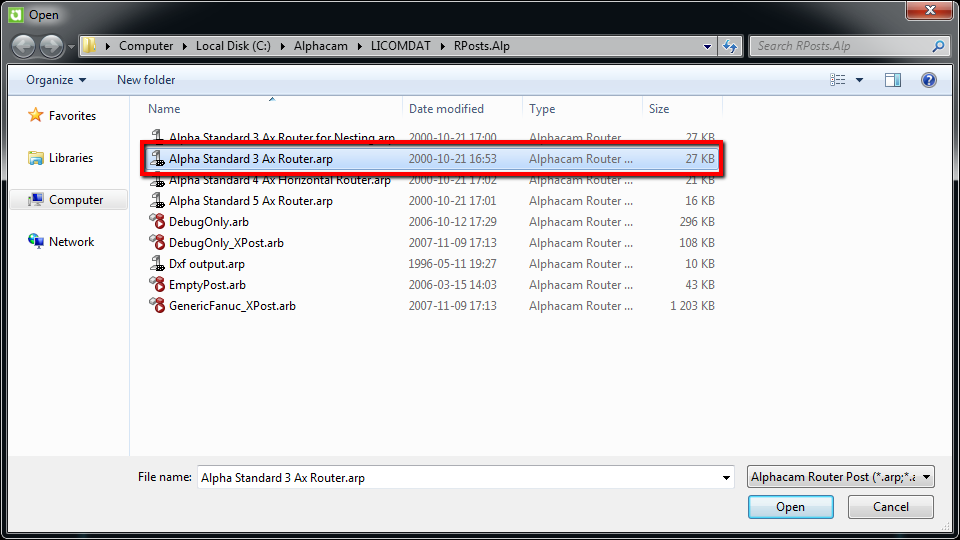

Let’s check the G-Code. First, select the required postprocessor. In this series of tutorials we will be using the Alpha Standard 3Ax Router postprocessor.

Waht is the postprocessor? In short, the post is a kind of translator.

It translates tool paths from CAM software to specific G-Code.

From the Home Tab, select option: Select Post…

Window shown below will appear.

The default folder for postprocessors is C:\Alphacam\LICOMDAT\RPost.Alp

RPost for Alphacam Router (RPost = Router Post), MPost for Alphacam Milling (MPost = Mill Post).

Select Alpha Standard 3Ax Router.arp (arp extension means Alphacam Router Post) and click Open.

Now you can generate the NC code.

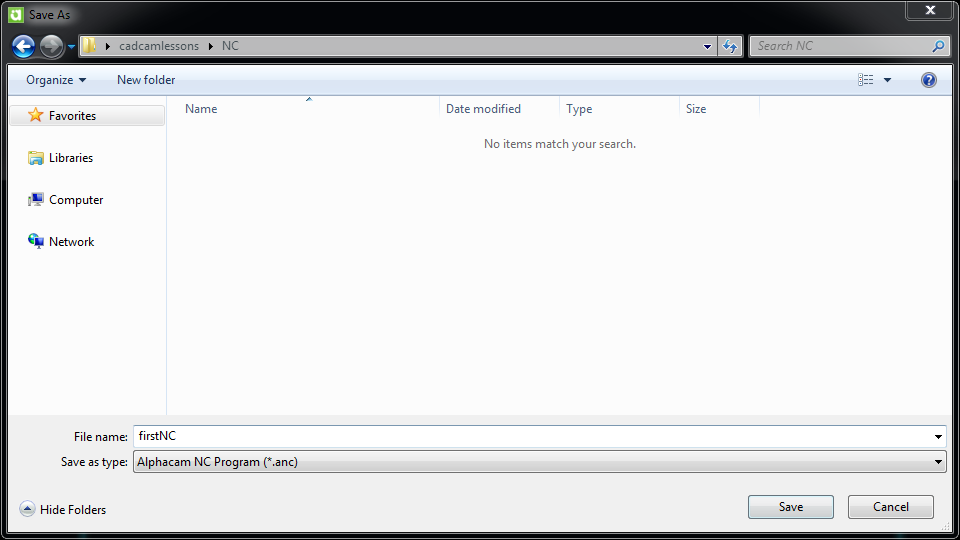

Select Output NC… option from Home Tab.

Window shown below will appear.

It is inform you about selected post (you can change it from drop down menu) and you can specify a location for the program. File, machine or both.

Alphacam allows you to configure DNC connection but this is advanced issue and we skip this for now.

Click OK.

Now you have to specify location and name of NC file. Click Save.

Window shown below will appear.

This post allows you to specify Program Number. You can type program number or leave it empty.

Click OK.

You will be notified that you NC program was saved.

You can open this file and check the NC code.

Operation List POST: Alpha Standard 3 Ax Router

--------------------------------------------------

OP 1 FINISH PASS TOOL 3 FLAT - 10MM

EFFECTIVE DIAMETER 10

Feed Distance: 600 Time for OP 1: 1m 30s

--------------------------------------------------

Total Feed Distance .......................... 600

Tool Change Time .......................... 0m 10s

Total Time ................................ 1m 40s

--------------------------------------------------

Material: MDF

Use Extraction

--------------------------------------------------

START

'(FIRSTNC)

%

:1234

N10 (PROGRAM PRODUCED - 06 AUG 16)

N20 G90 G71

N30 G40 G80

'(OP 1 FINISH PASS TOOL 3 FLAT - 10MM)

'(EFFECTIVE DIAMETER 10)

N40 T0303 M03 'Select tool and offset

N50 S999 H03 M06 'Next tool is 00, Next XY is 0., 0.

N60 G0 X0. Y0.

N70 G43 Z0. H03 M09 <--- This is wrong!!! We have Rapid move G0 to Z0

DN

N80 G1 X200. F400

N90 Y100.

N100 X0.

N110 Y0.

UP

N120 M09

N130 M30

%

This is our first NC program and we have some errors. We have rapid move G0 to Z0 and this could cause collision.

We will discus it in the next lesson.

If you find my tutorials helpful, you can support CADCAMLessons:

https://ko-fi.com/cadcamlessons