Heidenhain Helical Milling – CYCLE 208

YouTube: https://youtu.be/KfM6clqyLmo

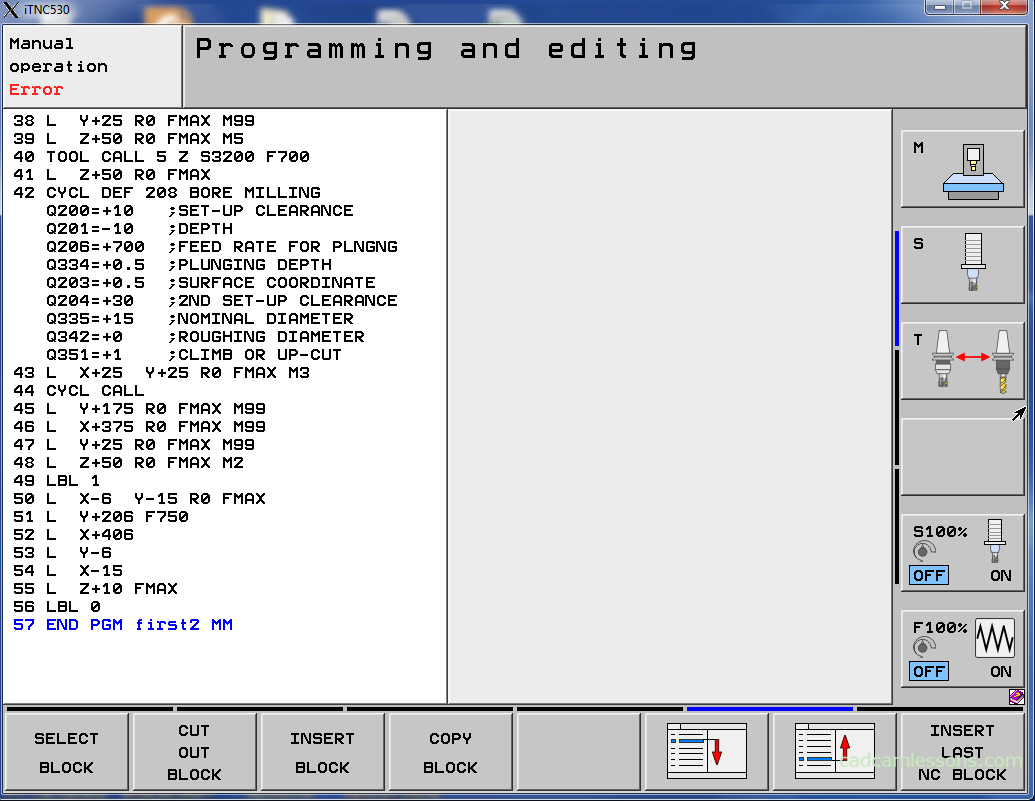

In this lesson we will discuss about helical milling in Heidenhain. In Hedenhain it is cycle 208 BORE MILLING.

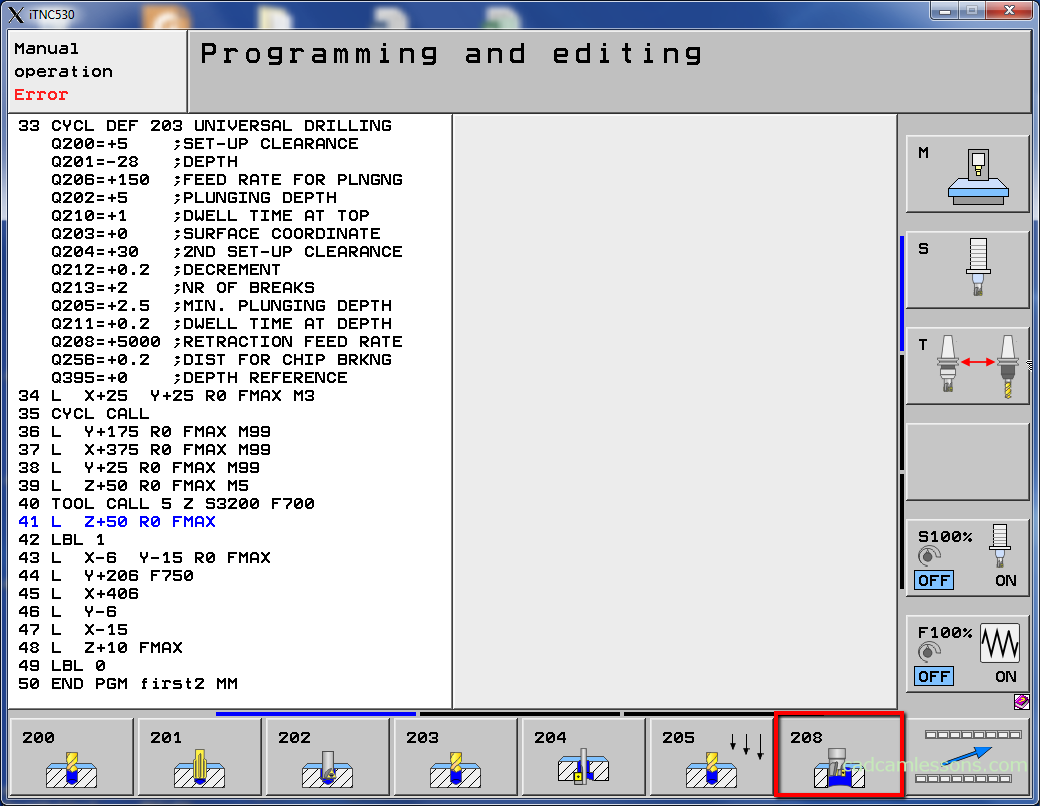

Highlight the line 39 and press TOOL CALL button to call new tool and press SELECT softkey.

From the tool table select T5 D10 and enter Z S3200 F700.

And add L Z+50 R0 FMAX.

Press CYCL DEF button to define cycle, select DRILLING/THREAD.

Select cycle 208.

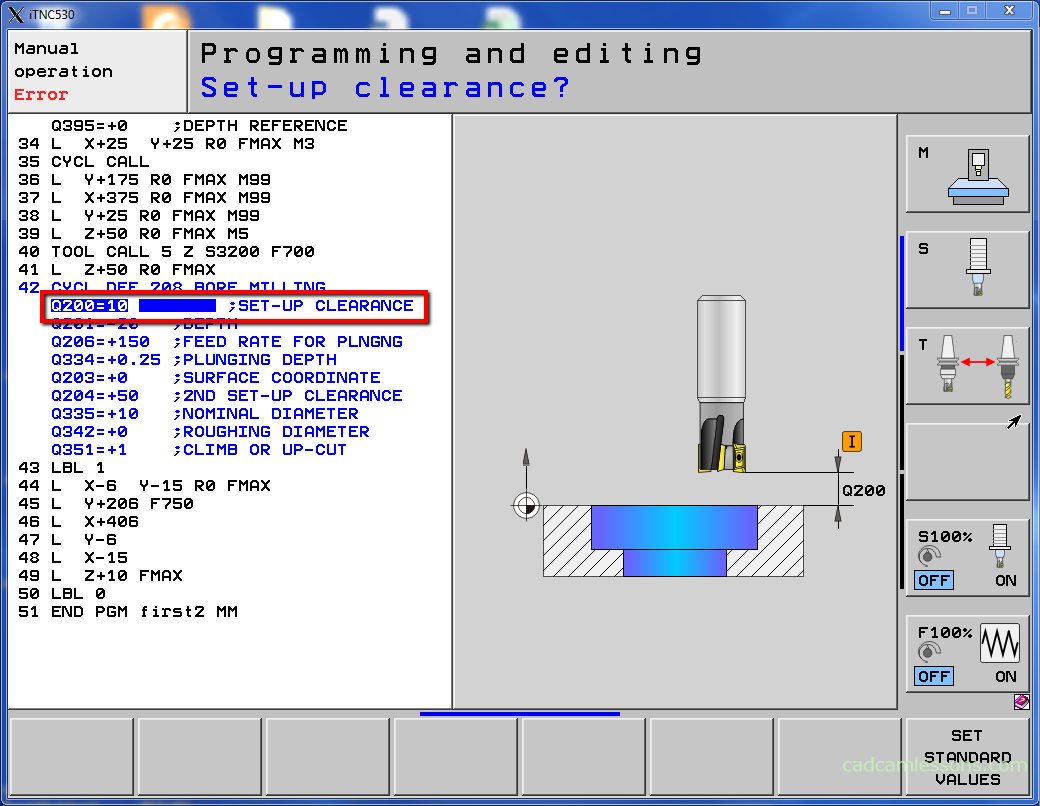

First parameter is the set-up clearance – Q200.

Enter 10 and press ENT button.

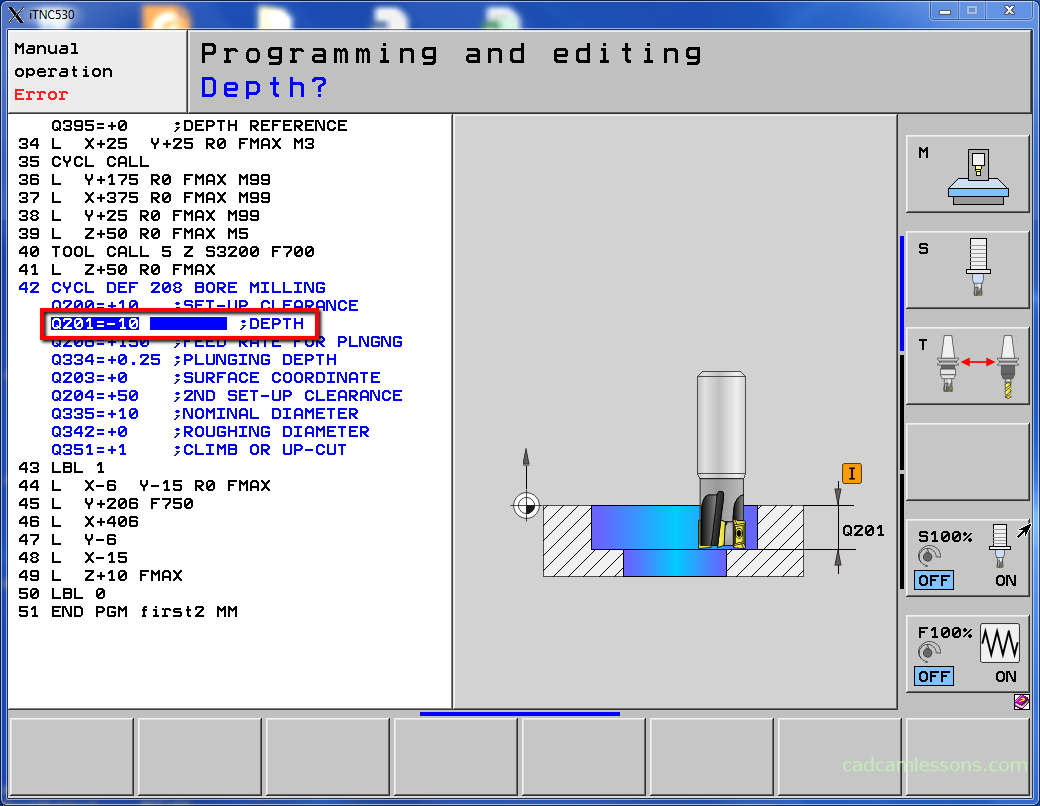

Next parameter is the depth – Q201.

Enter -10 and press ENT button.

Next parameter is the feed rate for plunging – Q206.

Enter 700 and press ENT button.

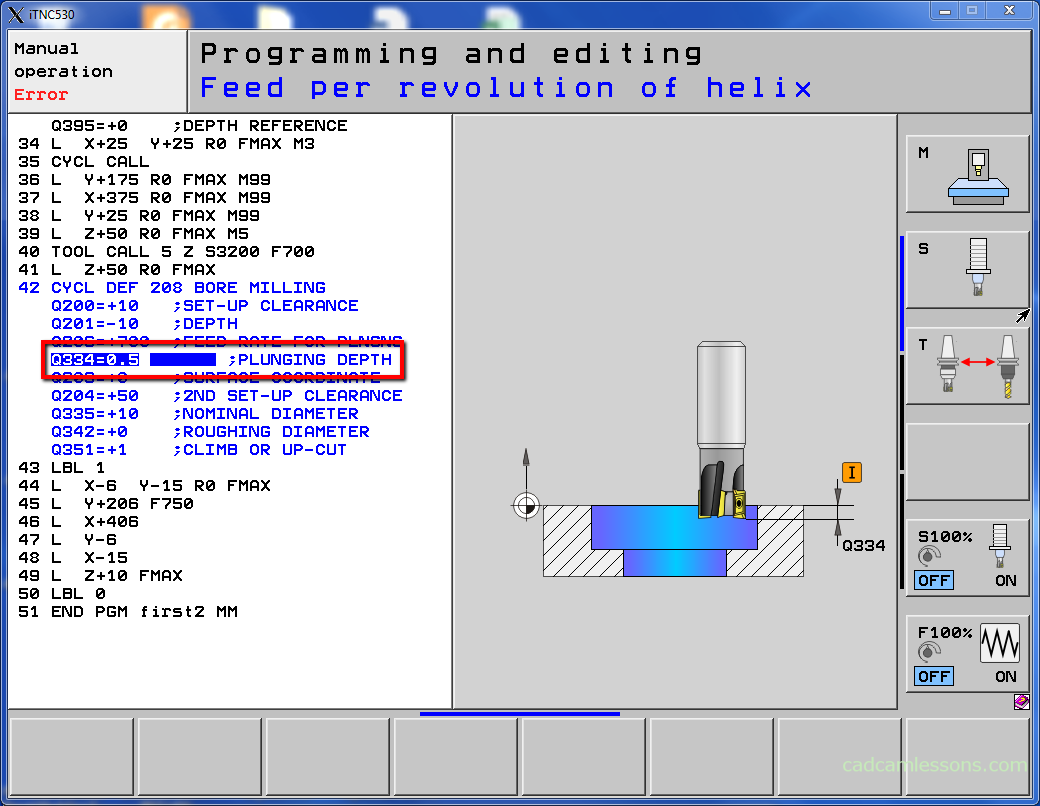

Next parameter is the plunging depth – Q334.

This is depth of one full (360 deg) helix (helix pitch).

Enter 0.5 and press ENT button.

Next parameter is the workpiece surface coordinate – Q203.

This is the Z level on which the hole starts. It is 0, but for safe we can enter 0.5 to make sure that cycle starts little bit above the material.

Enter 0.5 and press ENT button.

Next parameter is the second set-up clearance – Q204.

Enter 30 and press ENT button.

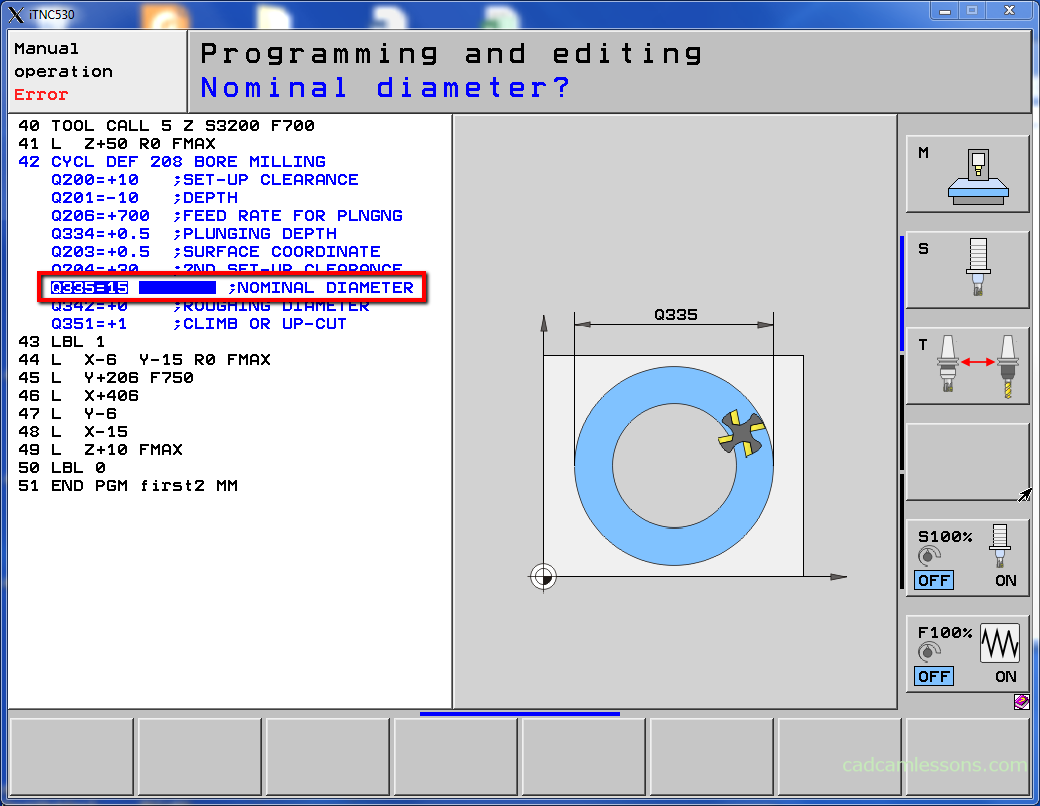

Next parameter is the nominal diameter – Q335.

This is the diameter of the hole we want to get.

Enter 15 and press ENT button.

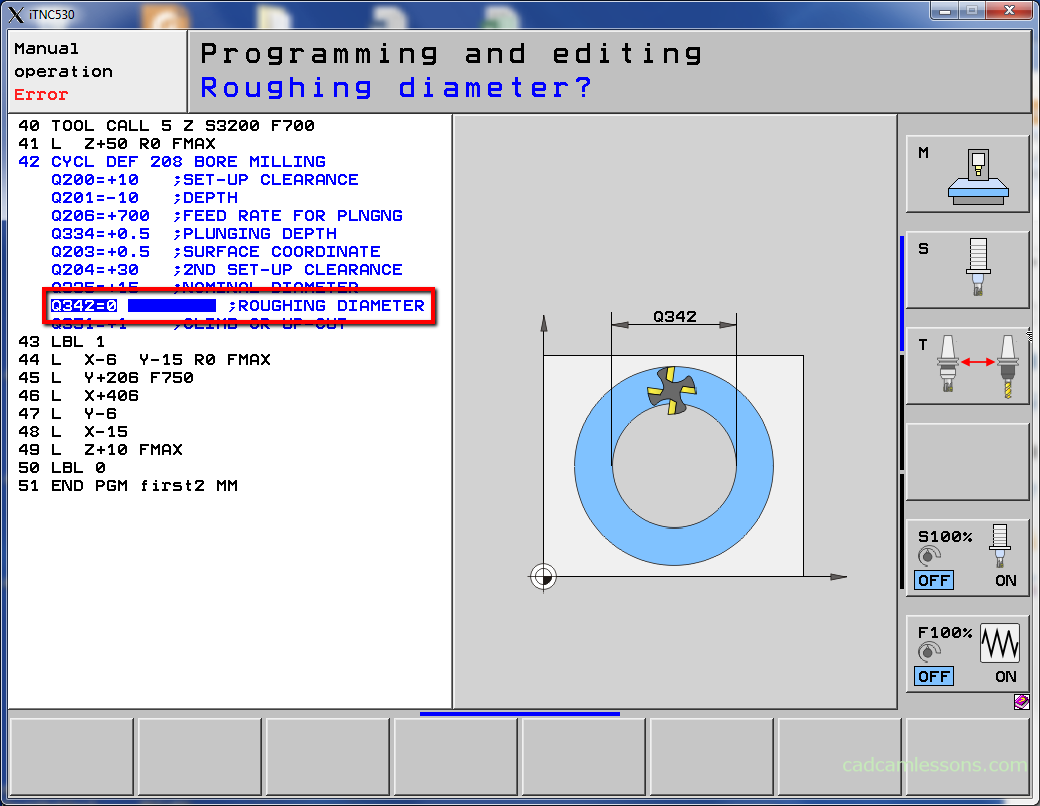

Next parameter is the roughing diameter – Q342.

If we enter a value greater that 0, the we have the possibility to mill a circle with a diameter greater that twice the diameter of the tool. If we leave 0, the maximum diameter of the hole (Q335) can be twice the diameter of the tool (so that not to leave unmachined material inside the hole)

Enter 0 and press ENT button.

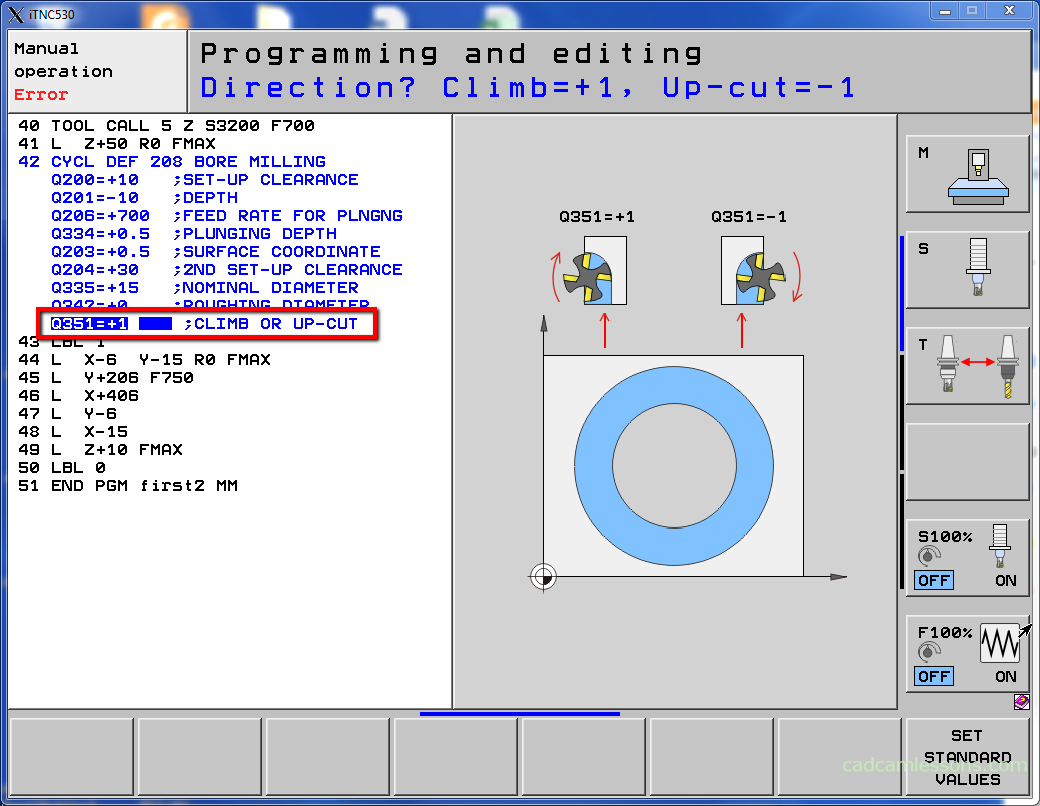

Last parameter is the direction of the milling, climb or up-cut – Q351.

Enter 1 and press ENT button.

Let’s preposition the tool above the first hole and call the cycle.

Line 43: L X+25 Y+25 R0 FMAX M3 is the positioning tool for drilling first hole.

Line 44: CYCL CALL is the calling the cycle.

Line 45: L Y+175 R0 FMAX M99 is the positioning tool for drilling second hole and calling cycle.

Line 46: L X+375 R0 FMAX M99 is the positioning tool for drilling third hole and calling cycle.

Line 47: L Y+25 R0 FMAX M99 is the positioning tool for drilling fourth hole and calling cycle.

Line 48: L Z+50 R0 FMAX M2 is the tool retract and finish the program

Save the program and run simulation.

This is the last lesson of the Heidenhain Tutorial for Beginners.

If you find my tutorials helpful, you can support CADCAMLessons:

https://ko-fi.com/cadcamlessons