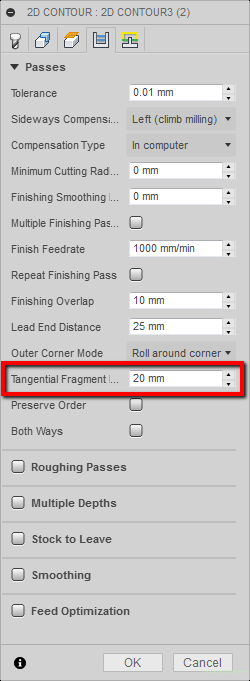

Tangential Fragment Extension Distance

Another parameter that will allow to adjust the passes is the Tangential Fragment Extension Distance parameter.

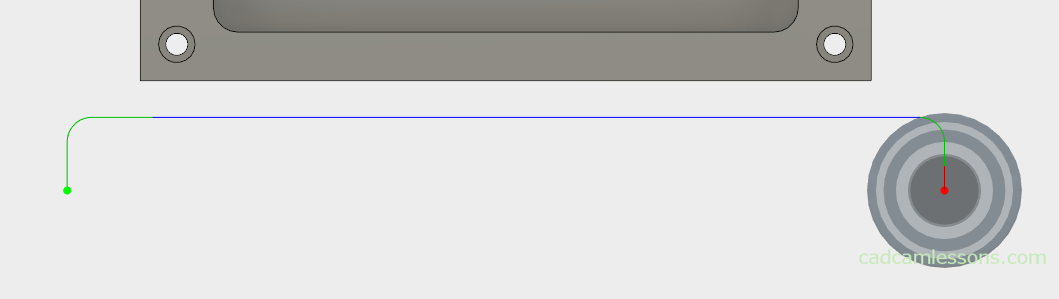

This option is rateher applicable to open contours. The tool path wusing this option will look like the picture below.

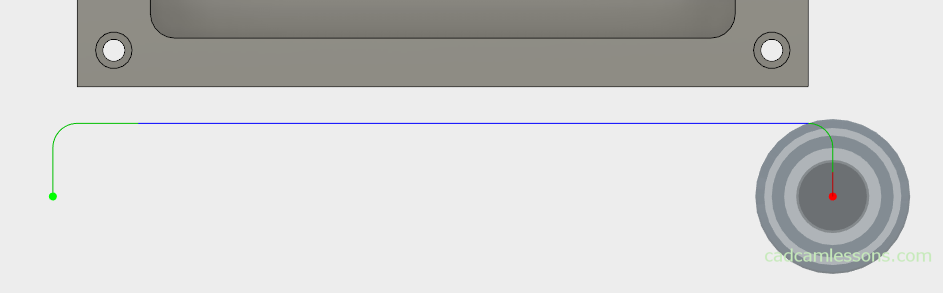

Without using this option, the tool path will look like in the picture below.

You can clearly see the extension of the tool pathat the beginning and end of the contour. In the case of machining open contours, this option will be very useful.

Another option is the Preserve Order. In the case of several different geometries, when this option is selected, geometries will be machined in the order in which they were selected. So we simply force the order of machining to exactly what we want.

Both Ways

The last option I would like to discuss in this post is Both Ways.

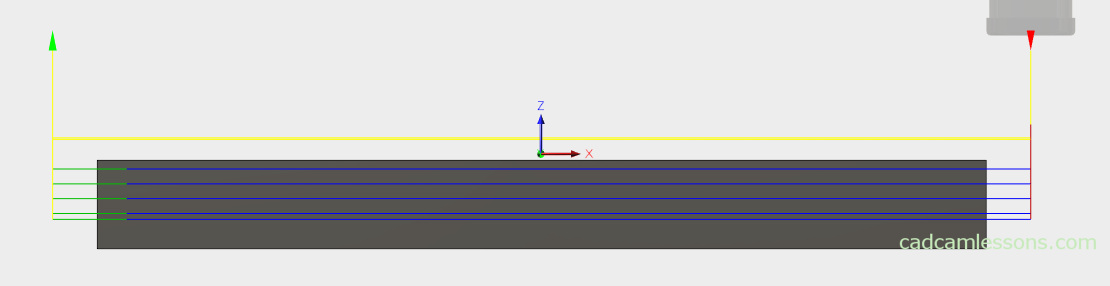

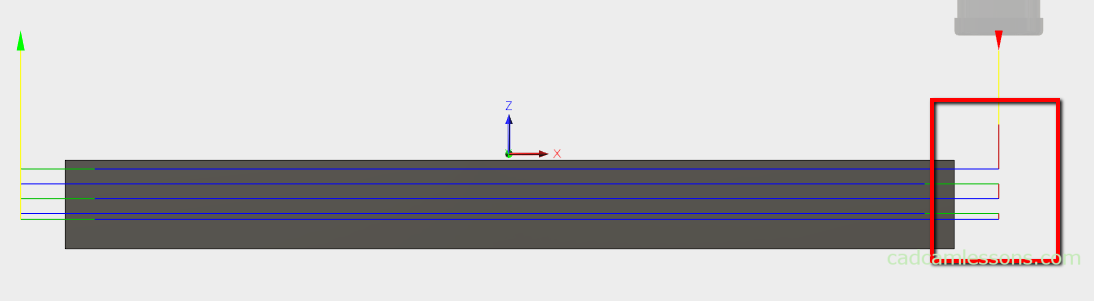

This is the tool path without the Both Ways option selected.

After the contour machining to the depth of the first path, tool will retract and move quickly to the beginning of the next pass, move to the depth of the second pass and start machining the next pass.

The advantage of this solution is that we have preserved the selected method of machining: climb or conventional milling. The disadvantage is that after each pass we have a movement in the air to the beginning of the contour. In the case of short parts, this is not a problem and time loss will not be too big, but in the case of long parts, these movements will be noticable and this can significantly affect to the time of the entire machining.

When you select the Both Ways option, the tool paths looks like this:

The tool after machining at the first pass depth does not retract and does not return to the beginning of the contour, only goes to the depth of the next pass and continues the machining from the end of the contour. In the case of this solution, we have a climb and conventional milling in one operation, but we do not have a movements in the air. Selecting this option may be the first step to shorten the machining time, which is to reduce the cost of manufacturing. And conventional milling is not so bad. If you have not tried to work this way, I recommend checking this method (unless it is a specific case, where the tool has to machine in climb way only). Typical milling tools e.g. end mills or milling heads, can mill in both ways, climb and conventional.

If you find my tutorials helpful, you can support CADCAMLessons:

https://ko-fi.com/cadcamlessons